What is a Soldering Iron? How is a Soldering Iron used? Why do we need Soldering? Is soldering going to last long? Why should we do Soldering?

Soldering is a very basic requirements in electronics which allows to join two components. Solder wire melted at High temperatures (180’c- 200’c) using Soldering iron or Gun to make solder joints is called Soldering. The very basic fundamental in the field of electronics industry is the need of Soldering. The world of electronics is based on the crucial role of Soldering.

Soldering can be done from Soldering Irons, Soldering Stations, Wave soldering machines etc.

The Tips of the Soldering iron are made from 100% Copper and are later plated on Nickel. Copper being an excellent conductor of Heat provides extensive support while soldering simple and complex joints.

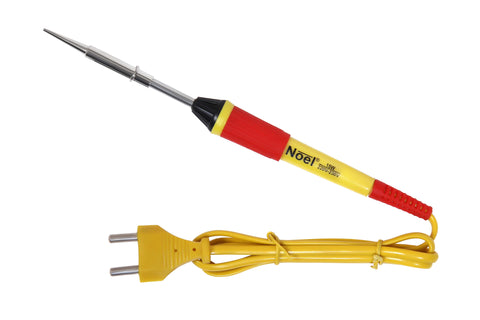

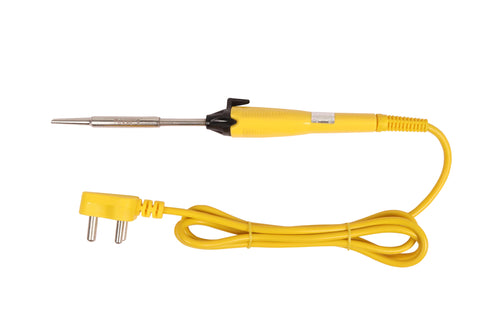

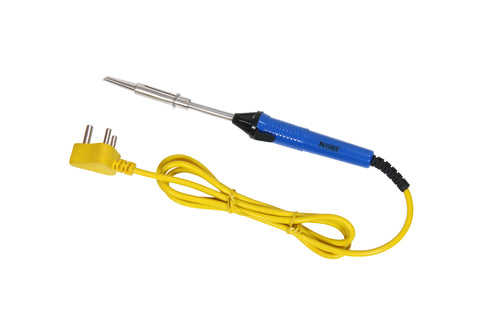

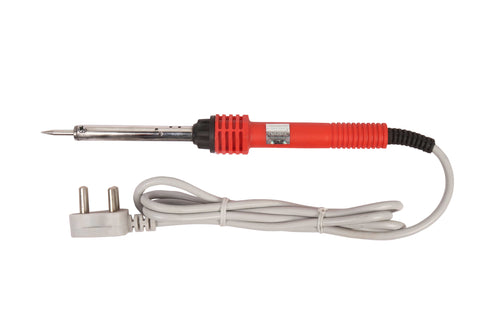

Constant Heating Soldering Irons

The very basic tool of Soldering is a Soldering Iron. The Soldering iron has a heat resistant insulated Handle, a heating element made out of Ceramic based or advanced Mica based connected to AC Power cord and a Copper based Nickel plated Soldering Iron Tip.

The heating element heats up the Soldering Iron which in turn heats up the Soldering iron tip used for Soldering. Soldering tips are available in various dimensions and shapes depending upon the use and requirements of various customers. For modern age components, sharp and thin bits are used for precise soldering jobs.

At Noel®, we have an extensive range of Soldering Irons. We manufacture constant heating Soldering irons as well as Temperature Controlled Soldering irons.

In Constant Heating soldering irons, we manufacture starting from 8W to125W.

These dispense heat according to their respective power wattage.

For basic Electronics work - 25W-40W Soldering iron are sufficient.

For extra Heavy soldering jobs -a user or technician can use anywhere in between 60W-125W. This include 60W, 75W, 125W Soldering Irons.

For best results, use Noel Soldering iron Tips only.

For excellent Hairline Soldering – Users can go for 8W and 15W& Micro Soldering Pen 12V DC

Temperature Controlled Soldering Irons

At Noel, we seek new possibilities!

We have developed Temperature Controlled Soldering irons which provide advanced heating regulation on the Soldering iron Bit.

The ultimate disadvantage to unregulated Bit temperature damages fragile components like ICs. Controlling the temperature of the soldering iron gives advantage to the user. The user can define limits of temperature of the heating element of the soldering iron, which regulates the temperature of the Soldering bit on the iron ultimately.

Micro Controlled Chips in Soldering Irons

Noel®has now introduced a well-designed Micro controlled Chip on the soldering iron which controls the Temperature and modulates heat. Temperature of these Soldering irons can be modulated from 200’C- 500’C. This advanced Heating technology can be used for Leaded and Lead-free Solders without spattering,

The micro controlled LCD Display shows the temperature on which the user is using the Product. For continuous working and stress-free handling, Noel®Temperature controlled Soldering irons are a great ease.

The user of Noel®temperature-controlled soldering irons can regulate the heat by +-1’C just by pushing simple buttons on the Soldering iron itself.

Noel ®has launched two Temperature Controlled Soldering Irons:

- 1. Analog Temperature Controlled Soldering Iron 60W

- 2. Digital Temperature Controlled Soldering Iron 90W

To provide sufficient heat, Analog Temperature Controlled Soldering iron 60W temperature can be regulated just be revolving a regulator/thermostat present on the Soldering iron, whereas, on Digital Temperature Controlled Soldering iron 90W, the temperature can be controlled by pressing buttons on the Soldering Iron.

Standard Voltage

Our Products are currently designed and suitable for the Indian market where in we are supplied 220V-240V.

Maintenance of Soldering Irons

While performing Soldering on joints, the user should always clean the Soldering iron tip with Wet Soldering Cleaning Sponges regularly after certain joints are soldered.

This not only helps in the longevity of the Soldering Iron tip life, but also the Heating elements.

Longevity of Life

Do not File the bits from the top to remove carbon. Filing of Tips reduces the life of the Soldering iron and even creates possibilities to have a hole in the Tip.

MANUFACTURING AT NOEL

We, Noel Precision Products are one of the largest manufacturers in India. With an experience of over 30 years now, we have our presence across the country. Our trust with our dealers and distributors have made our presence we more wide PAN India basis.

Our product line includes – Soldering Irons, Desoldering Pumps, Solder Fluxes, Solder Wires, Soldering Stations, Soldering Spare Bits & Elements, Soldering Accessories etc.

We are amongst a few brands which are sticking to their core business and developing niche in the segment of SOLDERING & DESOLDERING.